Moving towards more sustainable construction through green concrete solutions

Betolar has developed a type of concrete that does not require cement. European standards must be amended to allow the use of alternative concrete solutions in construction.

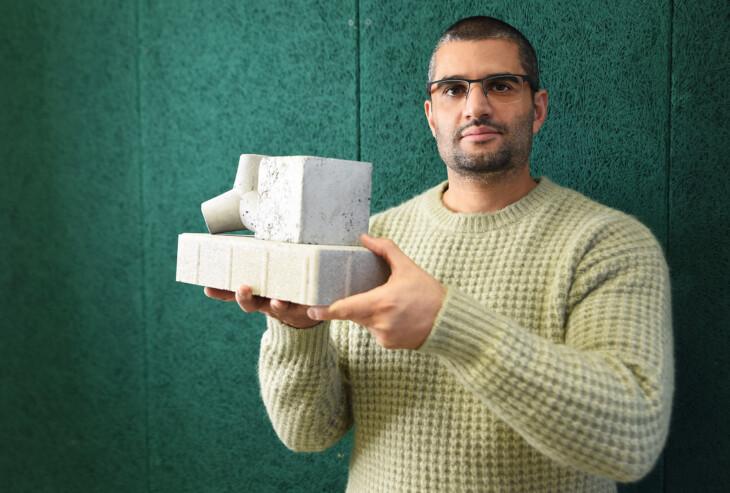

The grey block looks just like regular concrete. It feels just as heavy and durable.

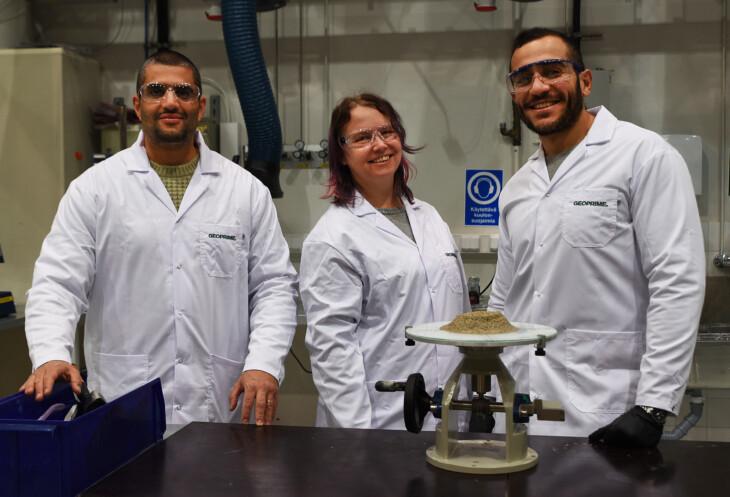

However, this construction material is fully cement-free and therefore more environmentally friendly than regular concrete. Geoprime is an innovative construction material where cement has been replaced with alternative binders sourced from industrial side streams such as fly ash, blast-furnace slag or tailings from the mining industry.

Geoprime has been developed by the Finnish company Betolar. Betolar aims to make construction more sustainable and environmentally friendly. The company’s objective is to reduce carbon dioxide emissions and the use of natural resources in construction while transforming industrial side streams into a sustainable business.

“It’s all about reducing emissions. Construction accounts for around 20 per cent of all CO2 emissions at the global level. The greatest individual source of emissions is the cement used in concrete production. Globally, cement production accounts for around 7 per cent of all CO2 emissions,” says Betolar’s Product Development Director Hassan Raad.

Replacing concrete would be challenging. As a convenient and durable construction material, concrete has proved itself as a solution to many societal issues. For example, concrete construction has improved the quality of low-income housing.

It is clear, therefore, that the need for this tried-and-tested construction material is unlikely to disappear. However, unless alternatives to cement are introduced, materials for concrete production may account for as much as 30 per cent of the world’s CO2 emissions by 2050.

“This cannot be allowed. This is why Betolar is focusing on new opportunities and product development, which has already produced positive results.”

Betolar is currently testing the viability of more exotic materials such as incinerated rice hulls, coconut husks and shrimp shells as replacements for cement.

Progress is hindered by standards requiring the use of cement

The greatest obstacle to the development of green concrete is posed by current standards and the requirements they set for concrete. According to the current European Standards, Betolar’s innovation cannot be classified as concrete. This is because there is no cement involved. According to the standards, concrete must contain a minimum of 5 per cent cement.

In construction, compliance with various standards is mandatory. Betolar is now attempting to influence the contents of a key European Standard, driving for concrete to be defined based on performance rather than the materials used. In this way, alternative materials could be used in concrete production as long as the characteristics of the end product fulfil the requirements set for concrete.

“A definition based on performance is the most straightforward path towards more environmentally friendly solutions. This would help us achieve carbon-neutral concrete production by 2035,” Raad says.

Review of the Construction Products Regulation focuses on environmental impacts

The EU Construction Products Regulation is currently under review by the Council, Parliament and Commission of the European Union. As a result of the review, updates to the harmonised construction product standards are expected.

“It is also clear that there will be increased focus on the environmental impacts of construction products. This will affect the contents of previously harmonised standards,” says Heikki Väänänen from the EU Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs.

According to Väänänen, a key impact of the green transition on harmonised standards is that environmental impact assessment will be consolidated into the standards.

“Given that the green transition will bring about entirely new products and technologies, a need for harmonised standards may arise in certain new areas,” Väänänen predicts.

It is also clear that there will be increased focus on the environmental impacts of construction products. This will affect the contents of previously harmonised standards

Heikki Väänänen, EU Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs

He goes on to point out that products are not directly governed by the Construction Products Regulation as such.

“The regulation provides construction product manufacturers with a framework for describing the performance of their products in a consistent manner. This way, end users can choose the product that best suits their needs.”

Participating in standardization allows Betolar to influence future standards and industry development

Construction standards play a crucial role, as they impact the quality, safety and energy management of construction. Standards are also key in boosting competition. They make products, structures and buildings comparable.

Standards also provide reassurance to consumers and the end users of products. When a product has been manufactured according to the relevant standards, it is safe and healthy to use.

It is beneficial for companies in the construction industry to participate in standardization. For example, Betolar is a participant in the standardization group for concrete, thereby influencing both the related standards and regulations. Participation has also helped Betolar in its development of marketable products.

“What has surprised us the most is the fact that these changes take such a long time. It can take several years for any changes to be implemented in a standard.”

Raad wishes that Europe would look to the rest of the world for direction. For example, both Australia and the United States are far ahead of us in defining concrete in terms of performance.

Around the world, there are buildings constructed as early as 70 years ago using cement-free concrete. Although such technology is not new, Betolar looks forward to commercialising its own solution.

Betolar is placing its bet on the green transition

Will Betolar’s drive for innovation be thwarted by the slow pace of progress? Definitely not, says Hassan Raad.

“We simply need to have faith in ourselves. We know that the green transition is happening, and that there is no choice but to implement more resource-savvy solutions.

Betolar is currently implementing a voluntary, manufacturer-specific approval process for prefabricated concrete products. These include paving stones and tiles, concrete pipes and other infrastructure products. The objective is to enter the European market with the products within a few years.

Read also

How can I participate in standardization

Standardization in Finland and globally

European Commission: Review of the Construction Products Regulation